- High-Performance Doors for Every Industry

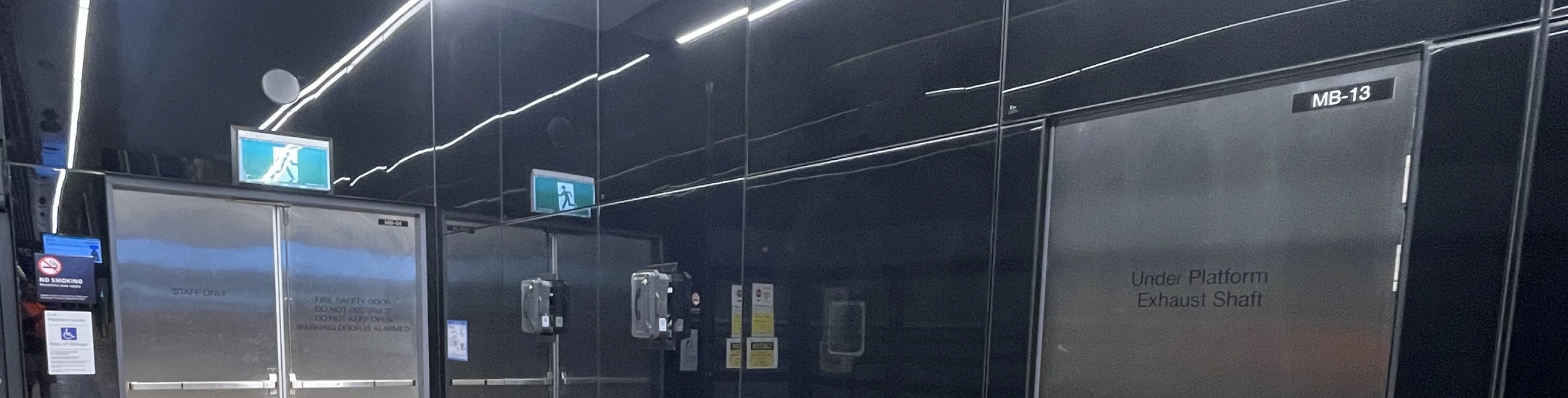

At BF Door Manufacturing, we specialise in custom door profiling, a highly accurate digital measuring and CNC-cutting process that ensures every door fits its frame perfectly, with no trimming, chiselling, or on-site modification required. Our profiling technology removes the guesswork from door installation, reduces on-site labour and improves fire-door performance, making it one of the most reliable and cost-efficient door preparation methods available in Australia.

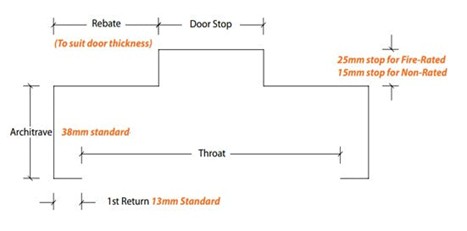

Door profiling is the process of creating a precise 2D architectural opening profile based on an installed door frame. A technician digitally measures the frame, including hinge positions, latch locations, and critical clearances. This digital data is then entered into our CNC machinery, allowing the door to be manufactured to the exact dimensions of the opening.

The result? A door that arrives fully prepared, hardware cutouts complete, accurate clearances applied, and ready to hang immediately.

Need help choosing the right hardware?

We start by gathering all project information, including:

This documentation allows our team to plan the profiling accurately. A technician then schedules an on-site measure.

Using advanced digital scanning tools, our technician captures the profile of each frame by defining measurement points around the opening. This creates a highly accurate 2D representation that mirrors the true shape of the frame, including hinge placement, latch locations, and opening tolerances.

Once complete, this data is sent to our manufacturing team for CNC processing.

The final step transforms the digital measurements into a perfectly cut door.

The CNC machine uses the profile to:

Your doors are then delivered ready to hang. No cutting, no chiselling, no on-site adjustment.

Note: As door profiling creates a 2D profile, axial twisting of the frame cannot be detected.

Installers can hang doors immediately, thanks to all the prep work being done during manufacturing.

Accurate profiling assists with AS1905 fire-door compliance, ensuring frame-to-door gaps do not exceed the 3mm requirement.

Reduced on-site labour means faster installation and earlier progress claims — valuable for contractors and project managers.

No cutting tools, reduced dust, and fewer workers required mean a safer, cleaner installation environment.

All hardware dimensions are programmed into our database, ensuring every hinge, lock, and latch is cut exactly to specification.

Ready to eliminate site guesswork?

From residential builders to large commercial contractors, we deliver directly to the site with reliable scheduling and careful handling to ensure every product arrives installation-ready. Our service area includes:

For larger projects, we can also coordinate staged deliveries to suit construction timelines and site access requirements.

Doors arrive fully profiled, so your installer spends less time on site. Fewer tools, no planing or chiselling, just lift, fit, and finish.

Profiling helps maintain tight tolerances. For fire doors, the critical 3 mm maximum gap is easier to achieve when doors and frames match perfectly.

Faster installs reduce labour hours and allow you to close out projects sooner, saving money on staging and site overheads.

No on-site trimming or sanding means less dust and mess, especially important for live environments like hospitals, schools, or occupied buildings.

Every door is cut on precision machinery, so the first door and the last door are the same.

Wall type, thickness, handing, hardware list, and clearances.

Brand, model, position for each item, or just attach your spec sheet.

Supply your paint codes or match to a brand like Dulux, Taubmans, or British Paints.

When you need your doors on site. We’ll work backwards from your program.

For retrofit profiling, we’ll help you measure any existing openings precisely and ask about our measuring guide if needed.

Our technicians carry out detailed on-site digital scans, capturing hinge locations, latch points, and exact frame dimensions. This ensures every door is manufactured to millimetre accuracy, providing a perfect fit when installed.

Profiling data is fed directly into our CNC machinery, allowing all cut-outs, clearances, and hardware preparations to be completed before delivery. This dramatically speeds up installation and improves overall project efficiency.

Accurate profiling helps maintain the strict gap tolerances required for fire-rated doors under AS1905. By controlling clearances during manufacturing, you achieve a compliant doorset without additional onsite rework.

With profiling, installers no longer need to trim or cut doors on-site. This reduces labour hours, minimises downtime, and supports faster progress claims, essential for medium and large-scale developments.

No cutting tools, no dust, and fewer workers required. Profiling contributes to a safer working environment and helps maintain site cleanliness, especially in operational buildings or sensitive environments.

Make installation faster, cleaner, and more accurate with professional door profiling from BF Door Manufacturing.

Whether you’re managing a high-rise project, a commercial fit-out, or a compliance-critical fire installation, our profiling service ensures every door fits perfectly the first time.