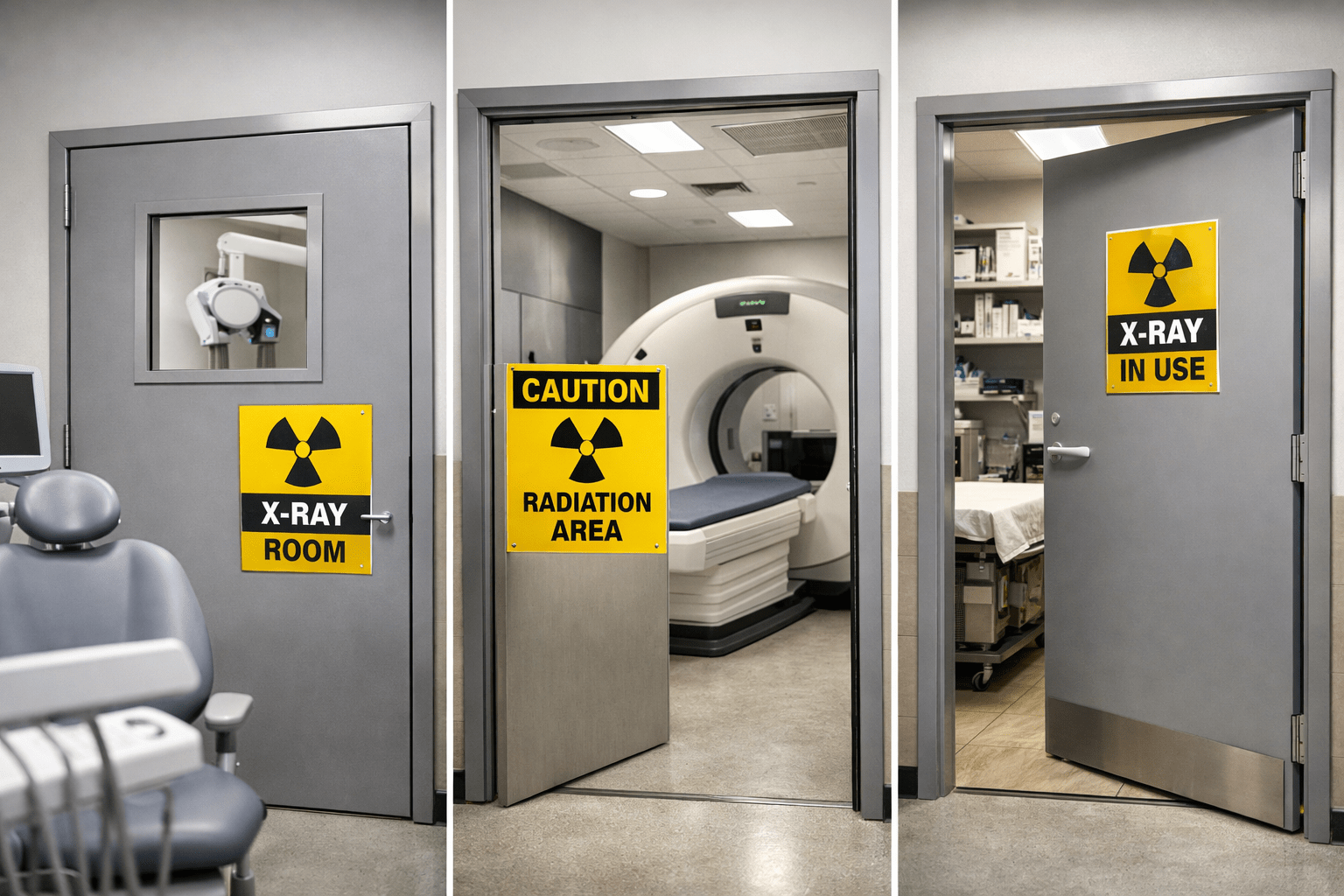

Radiation safety is a critical consideration in healthcare environments where X-ray and imaging equipment are used daily. From dental surgeries and medical imaging suites to veterinary clinics, protecting staff, patients, and visitors from radiation exposure is both a legal and ethical responsibility. This is where lead-lined doors play an essential role.

Designed specifically for radiation shielding, lead-lined doors help contain X-ray radiation within designated areas, ensuring facilities remain compliant with Australian health and safety standards. For clinics across Sydney, choosing the right door system, including construction, lead thickness, and finish, is vital for long-term safety and performance.

What Are Lead-Lined Doors?

Lead-lined doors are specially constructed doors that incorporate sheet lead within the door leaf to block radiation. The lead is pressed between the core and face materials, creating a continuous protective barrier that prevents radiation leakage beyond the treatment or imaging room.

These doors are commonly used in:

- Dental X-ray rooms

- Medical imaging suites

- CT and radiology rooms

- Veterinary clinics

- Research laboratories

They are manufactured to suit specific radiation shielding requirements, with lead thickness determined by equipment type and room layout.

Why Lead-Lined Doors Are Essential in Clinics

Radiation exposure, even at low levels, can pose health risks over time. Proper shielding is required to protect clinicians, patients in adjacent rooms, and the general public.

The primary benefits of lead-lined doors include:

- Effective containment of X-ray radiation

- Compliance with Australian radiation safety regulations

- Protection for staff and visitors

- Peace of mind for clinic operators

For Sydney clinics undergoing new builds or refurbishments, radiation protection is not optional. It is a core compliance requirement.

Customised Lead Thickness for Compliance

One of the most important factors in manufacturing lead-lined doors is the thickness of the lead sheet. Typical options range from 0.5 mm to 3.0 mm, depending on:

- Equipment output

- Frequency of use

- Distance to adjacent spaces

- Advice from radiation consultants

Doors can be produced with single or double layers of lead to achieve the required shielding level, ensuring the entire doorset performs as intended.

Special Finishes for Doors Without Compromising Safety

A common misconception is that radiation doors must look industrial or clinical. In reality, special finishes for doors allow lead-lined doors to blend seamlessly with the rest of the facility’s interior.

Popular finish options include:

- Paint-grade finishes for easy maintenance

- High-pressure laminate for durability and hygiene

- Timber veneer for premium medical suites

- Metal-clad finishes for high-impact areas

These finishes are applied without compromising the door’s shielding performance, allowing clinics to maintain a professional and welcoming appearance.

Integration with Frames, Hardware, and Vision Panels

For effective radiation protection, lead-lined doors must be part of a complete, coordinated doorset. This includes:

- Lead-lined or shielded door frames

- Radiation-rated hardware

- Lead-glass vision panels where required

Vision panels are often necessary for observation and safety, and can be supplied with certified radiation-resistant glass to maintain full shielding continuity.

Applications Across Dental, Medical & Veterinary Settings

Dental Clinics

Dental X-ray rooms require compact yet effective shielding. Lead-lined doors prevent radiation from escaping into waiting rooms or adjacent treatment areas.

Medical Imaging Facilities

Radiology, CT, and specialist imaging suites rely on high-performance radiation doors to meet strict compliance and operational demands.

Veterinary Clinics

Veterinary imaging areas also require radiation protection, particularly where staff may be present in surrounding rooms.

In all these environments, durable construction and reliable finishes are essential due to frequent use and strict hygiene standards.

Built for Durability and Long-Term Use

Beyond radiation protection, lead-lined doors are built for daily operation in busy clinical environments. Solid construction, reinforced cores, and quality hardware ensure:

- Smooth operation

- Long service life

- Resistance to impact and wear

When paired with appropriate frames and hardware, these doors deliver reliable performance for years.

Frequently Asked Questions (FAQs)

How do lead-lined doors protect against radiation?

Are doors mandatory for dental and medical clinics?

Can these doors be customised to match clinic interiors?

Do lead-lined doors require special frames?

What lead thickness is required for my clinic?

Can vision panels be included in radiation doors?

Are lead-lined doors suitable for veterinary clinics?

Protect Your Clinic with Certified Lead-Lined Doors

If your dental, medical, or veterinary clinic requires reliable radiation protection, our team can help. At BF Door Manufacturing, we manufacture lead-lined doors with compliant shielding levels and premium special finishes for doors, tailored to your facility’s needs. Contact us on 02 7247-2032 today for expert advice and a competitive quote for your Sydney clinic.